The utilization of surfactant foams for enhancement of oil and gas reservoirs has traditionally been challenged by in-situ instability, increasing chemical costs and reducing effectiveness. Capitalizing on this opportunity, CNERGREEN developed an innovative nanoparticle based foam, ArmorFoamTM, and looked to Exergy to assist in scaling up their production capabilities while supporting their flexibility as they broke into new markets.

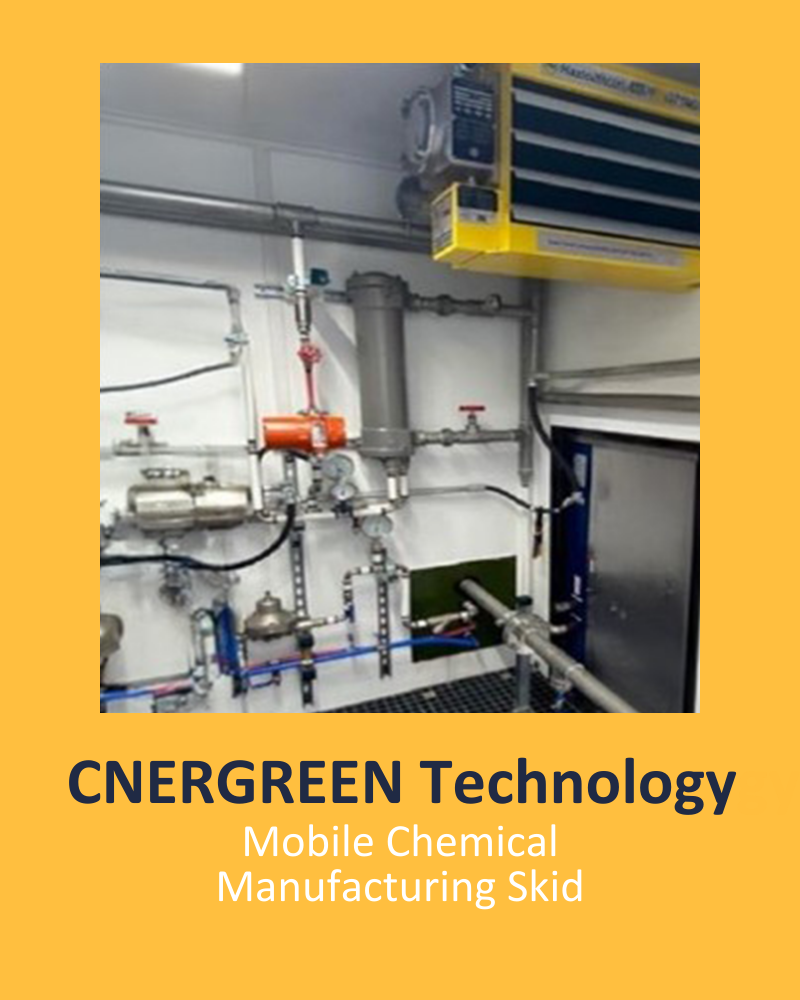

Our collaboration with CNERGREEN began with experimental and technical support to increase and optimize the throughput of their proprietary nano-particle stabilization technology. Once finalized, our team designed and fabricated a mobile standalone containerized manufacturing skid that could be deployed in a variety of locations and environments as CNERGREEN’s engagement with end-users progressed in parallel. This allowed them to stay agile and not rule out any potential opportunities as they worked to flush out their competitive niche.

The CNERGEEEN team ultimately chose to utilize Exergy’s Nexus facility as their temporary home for chemical production, occupying a dedicated bay. This allowed them to maintain a lean, capital light organization as they satisfied the chemical needs of the first few field pilots, approximately 10 tons each. Since then, on the back of positive field results, CNERGREEN has steadily increased monthly production to meet expanding demand, up to 100’s of tons per month and is now seamlessly moving into a larger permanent home, supported by the designed mobility of the manufacturing skid delivered by Exergy.

Be sure to follow the progress of ArmorFoamsTM deployment at https://www.cnergreen.ca/.

At Exergy we recognize that each project requires fit-for-purpose solutions to achieve the best outcome. Reach out to learn how we can help expand or commercialize your production in a cost-effective and efficient way. Let’s innovate together.