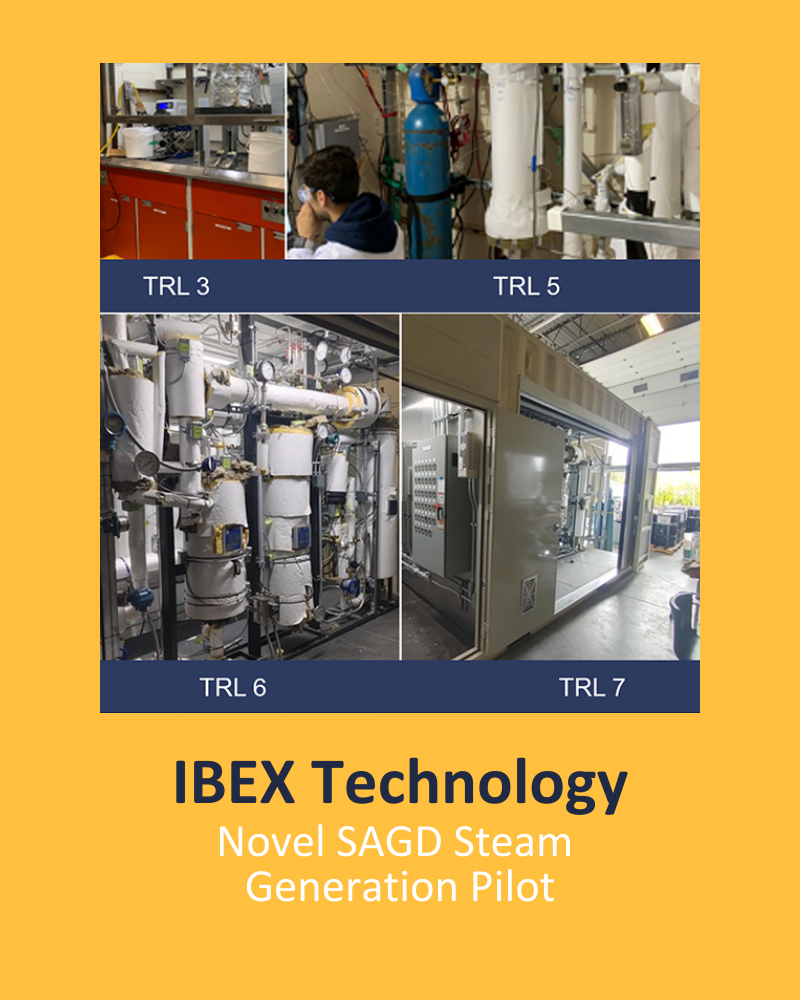

Steam Assisted Gravity Drainage (SAGD) is the primary way of producing bitumen from Alberta’s vast oil sands resources, but within the industry, SAGD plants are often seen as large water treatment plants that produce some oil as a byproduct. The resulting equipment costs and energy required presents a challenge for the industry’s competitiveness so a step change was required. When Archer BD reached out to Exergy with a new idea on how to reduce equipment, complexity and significantly reduce capital and operating costs, we provided engineering, fabrication, experimental space and operational support to get IBEX’s idea off paper and into a containerized prototype nearing its first field deployment.

Our engagement with Archer BD began in the lab, where our innovative teams designed and executed benchtop experiments as a proof-of-concept demonstration. These pivotal tests led to an initial design and a technoeconomic study that confirmed the design and value proposition. This led to an expanded bench program, designed, constructed, and operated by Exergy that showcased Archer BD’s proprietary contactor technology using pseudo-fluids.

Emboldened by the promising results and with additional investor backing, our teams seamlessly transitioned to engineering and fabricating a scaled-up unit, designed to operate with real process fluids at commercial temperatures and pressures. The test program, successfully hosted at Exergy’s Nexus facility, demonstrated the potential of the novel approach.

Our teams are continuing to advance this technology and are looking forward to the first field demonstration of the technology in 2025.

Be sure to follow the development of the IBEX technology at https://www.ibexsteam.com/.

Think you have a great idea but need some help proving it out? Reach out to learn more about how our team can assist you. Let’s build something great together.