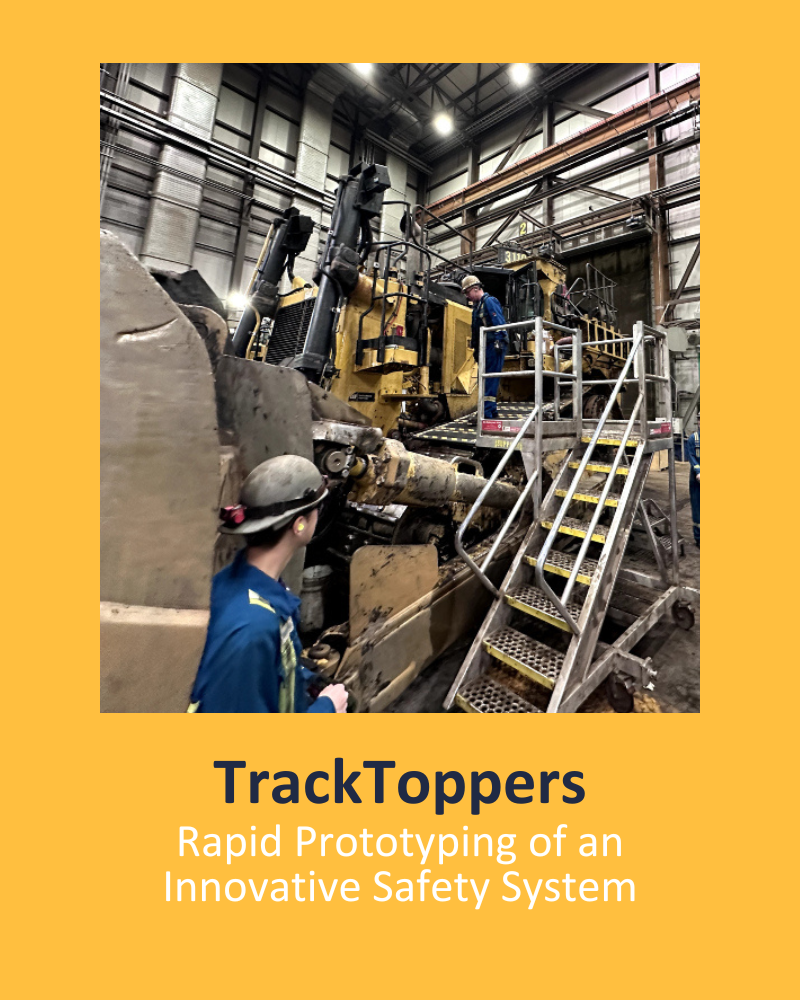

Confronted with a longstanding safety and ergonomic challenge for Heavy Equipment Technicians, Exergy was tasked with developing a stable, height-adjustable work platform that could adapt to both winter ice lugs and summer grousers and to deliver a field-ready solution in just 100 days. The urgency and complexity of this request demanded true engineering ingenuity. Our team rapidly mobilized, moving from concept to a field test ready TrackTopper system. Through six major design iterations, each informed by direct feedback from over 150 technicians across all shifts, the initial concepts were quickly translated into prototypes using in-house additive manufacturing, allowing for same-day design updates and compressing traditional development timelines by more than two-thirds.

The result is a commercial-ready platform that installs in about 30 seconds, integrates seamlessly with existing maintenance routines and parts washer systems, and addresses the unique demands of heavy equipment maintenance in harsh field conditions. Technicians immediately noticed the difference, reporting reduced fatigue and increased confidence in their footing: “With the TrackTopper system installed, I no longer have to worry about rolling an ankle on a grouser or ice lug. After just one shift, I already feel less fatigued.”

While Exergy’s in-house 3D printing accelerated prototyping, it was our deep engineering know-how, relentless problem-solving, and willingness to tackle the hard problems that truly set this project apart. By embedding our engineers alongside frontline teams and iterating rapidly based on real-world feedback, we delivered a solution that enhances safety, productivity, and user experience, demonstrating how Exergy’s commitment to innovation and operational excellence creates lasting value for our clients. If you have a complex challenge and an aggressive timeline, Exergy is ready to solve your toughest problems.